Time

Voortman v808 does not need to be trimmed with every nesting product. The V808 can reduce scrap to a minimum, which is a time-saving option. This is because the last cut of one product is also the cut of the next. The V808 can import DSTV+ and VACAM files. VACAM's beam-nesting module allows continuous nesting to ensure that you get the best product from every stock length.

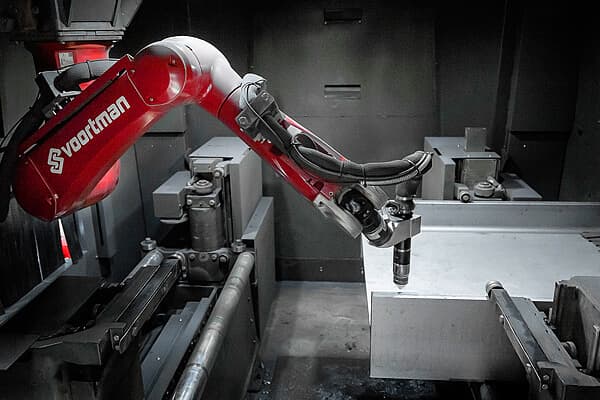

Gulf States Saw & Machine Co. is the market leader 3D pipe profilers for over 35+ years. They were the first to offer a robot beam profiling machine capable of cutting all saddles, chamfers or slots: the RPC 1200 Mk3. We have fulfilled a long-standing customer demand by creating a beam-coping machine that profiles beams, channel, square tubes and angle bars as well as pipes, plates, t-bars and bulbs.